Curbing

Do You Have A Project We Can Help With?

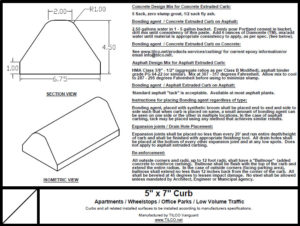

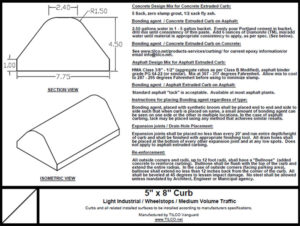

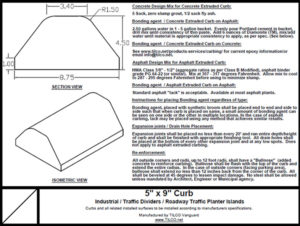

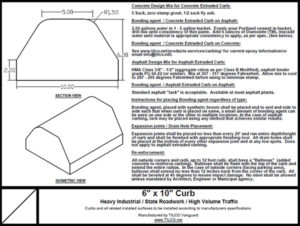

Extruded Curbs

Why do we propose 5 inch tall and even shorter curbs over 6 inch tall curbs?

Pretty simple. Many cars today have smaller wheels and tires than cars of years past, putting the impact on a 6 inch tall curb on the side instead of on the top. Shorter curbs are stronger than taller curbs.

Physics.

If the impact is no longer “top-down” on these older curbs, then failure is more likely than with a shorter one. Any 5″ tall curb will stand up to impacts longer, with less ongoing damage or wear.

Steel in extruded curbs:

Extruded curbs get their strength from how well they’re bonded to the surface. Nothing else. Bonded properly, an extruded curb should rip up the substrate if it ever fails. Not bonded properly, with steel, the steel will actually help carry out the curb with ongoing impacts.

There are two types of steel placement typically called out for extruded curbs; horizontal, and vertical.

Horizontal assumes strength gained from a lateral advantage. If the bond to the substrate is weak, it’s only logical that this added steel will aid in pulling out the remaining curb with every impact, not help keep it in place.

The cost to remove it once it does fail thanks to the added steel, will be needlessly excessive.

The debate against vertical steel doesn’t require much effort at all; If it was ever valid, what about the space in between, where there are no steel pins? What about basic energy transfer taught in science? Wherever the curb is impacted, all energy transferred must be dissipated. (An easy, if imperfect visual would be lightning rods).

The first place that energy is going to run to is…the steel pin or rod. The first place the curb will fail…is the steel pin or rod.

Steel placed in a formed curb (buried 12 inches deeper in to the soil, therefore providing a structural anchor) actually strengthens that curb. Steel placed in extruded curbs (bonded properly to a hard surface…its anchor) actually weakens…and even damages the curb.

It also makes it vastly more expensive to repair, in some cases, just a few years later.

It seems counterintuitive but it’s what we’ve built our business on.

Bonding:

The formula for the best bonding agent for extruded curbs (placed on asphalt) is: 1 empty 5 gallon bucket. Add 2+ gallons of water. Add Portland cement in and mix with drill mixing bit until material is evenly mixed and about the consistency of thick paint, add 16 ounces of Diamonite admixture, continue mixing until all components are evenly distributed (see this vid beginning at 10 seconds: Bonding agent video). Apply with synthetic house broom as if it were paint, enough such that when curb is placed over top of same, a nearly indiscernible amount squeezes out of each side…finish curb with appropriate trowel…rinse, repeat.

Works every time.

The only exception to the above; when extruded curbs are installed on top of concrete. Only at that time is a a two part chemical epoxy a better design standard.

In summation: For extruded curbs, shorter is better than taller, it uses less material. It’s better for the environment meaning fewer trips to pick up, less CO2 etc. and, it will last longer using the most basic physics.

No steel is always better than any steel and…. the best bonding agent isn’t some high tech chemical concoction, rather, the simple formula shown above, and it’s still today, the best bonding agent out there and the only one we’ll warranty.

Speaking of warranties; TILCO Vanguard is the ONLY curbing company in the entire USA that warranties their curb installations for a full FIVE years!

Yes, you read that right. FIVE years.

If you use our 5 inch tall designs and don’t put steel in them, we will warranty them from failure to adhere to the asphalt surface for a full five years.

Residential, commercial, office, industrial.

If they come loose in that period of time and do not bring up the asphalt below it, attached to our curb, we’ll repair them for free.

Five years.

How do we do that? It’s so simple, anyone can do it (but they won’t): It’s our bonding agent and the most basic laws of physics; Shorter curbs will always withstand impacts from tall things better than taller curbs will.

(It’s not complicated).

And, it works. Every time.

We’ve been here since 1977, and we’re not going anywhere.

Just like our curbs.

The difference between good and great is almost always; Experience.

TILCO Vanguard has more than 48 years of it (more than anyone else in the entire Puget Sound).

It really does matter who you choose to do your curbing.

Give us a call at 425 483 5700 or email us at BidRequests@tilco.net

Our Customers Say It Best

“Thanks Jon for your snow reports. Because of your report I put the plow on the truck Monday night. We got an inch starting at 6:30 AM to 7:30 AM. After using the plow on Fortuna hill for an hour the snow started melting as it warmed. Your heads up definitely helped the campus prepare for this event. If I had relied on AccuWeather I would not have been prepared.”

“…I’ve had the pleasure of working with TILCO Vanguard for the past four (4) years, and unlike that of many vendors, their service has actually improved over time. I am continually impressed with their responsiveness, ability to create solutions, and overall care for our properties. I regularly feel as if I’m their only client…My advice to other property managers: Hire TILCO Vanguard, and let them do what they know how to do best.”

“…Your product has held up very well in the past six months. When I was on site recently, all domes were intact and there was no sign of the color fading. Your product still looks like it was installed yesterday…”